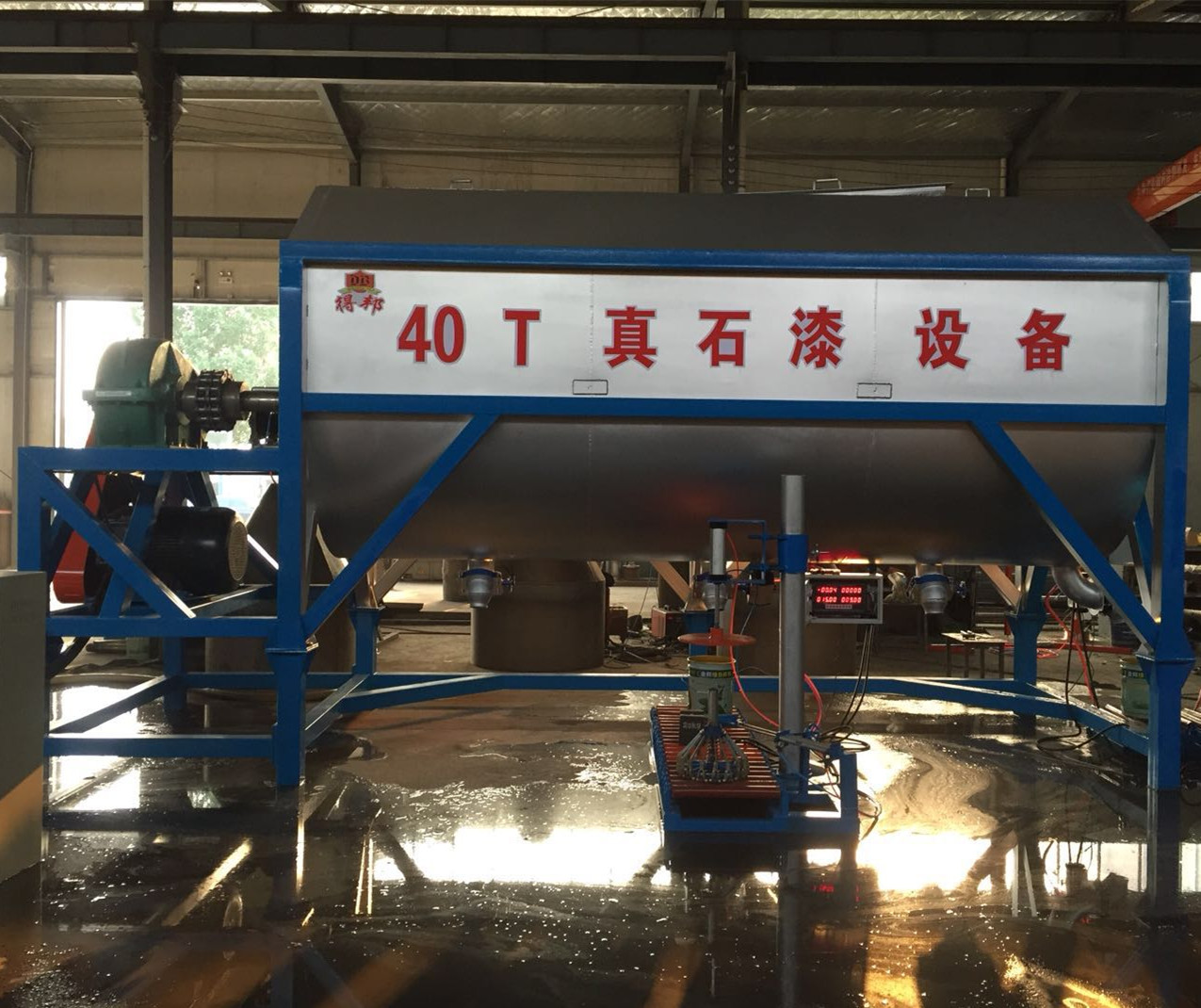

Paint production line

1.Powder at the bottom of the vacuum feed

Powder using vacuum feed way, at the bottom of the feed, distance is short,fast feed speed, automatic control. It can avoid slurry flow back due to inaccurate manual operation and .evacuation. Sucked into the powder by water around, there is no dust pollution and congestion, which can realize continuous suction powder, 2 minutes can absorb 500 kg powder, high efficiency.,but traditional vacuum materials, powder from the roof to inhale,it need to 25 minutes to finish absorption, and powder is easy to be vacuum and adhesion of tank wall,it will cause material loss.

2.Double strong dispersion plate

Core component of the whole equipment is a high-speed dispersion machine, and the focus of high-speed dispersion machine is scattered disk, so dispersion plate is to improve the production efficiency and quality of top priority. Double strong dispersion plate adopt wear-resisting material, high shear force, line speed, separate efficiency is a few times of a traditional dish .

3.Without cooling water of the mechanical seal

The traditional equipment is exposure to the drum,use artificial feeding way, dust pollution. Whole sealing mode of production, the company I used vacuum negative pressure feed, high-speed dispersion machine installation in the sealed container, no dust pollution. High-speed dispersion machine cooling water of the mechanical seal, NSK bearings, elastic coupling, such as technology, quality assurance, maintenance is convenient.

4.Fully enclosed manhole

A complete set of equipment for all the seal, vacuum negative pressure conveying, if tanks untight seal will cause the whole equipment cannot be used. Manhole in the sealing silicone often contact materials in the process of operation can cause untight seal, our company make the seal more closely