Debang improved its lab and batching room in 2012. The company also offered multi-series and multi-class paint products and equipment for different market and customers. It provide most advanced technique, equipment, procedure to help customers to produce low cost, environmental, long lifetime products.(Debang equipment and technique business has expanded to many domestic and international market. It provided more than 3000 paint producing factories with equipment and technique services. Debang’s product and technique is all over China market and is entering Asian and African market. Its best product and services has won good reputation.

1. Product introduction

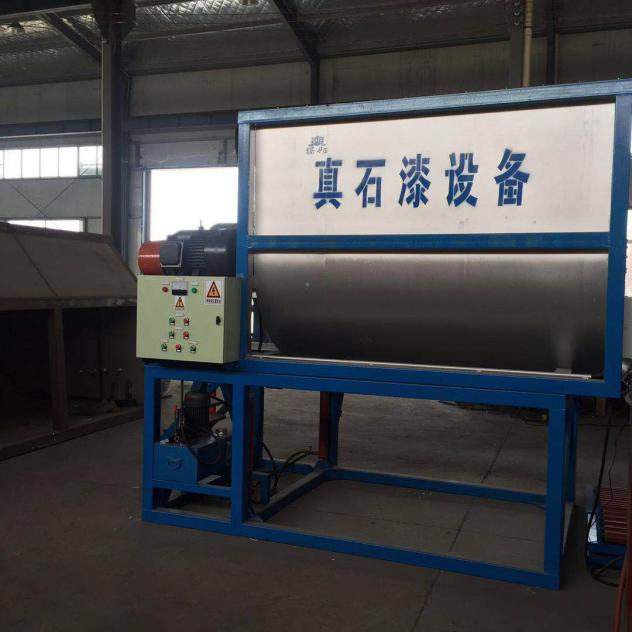

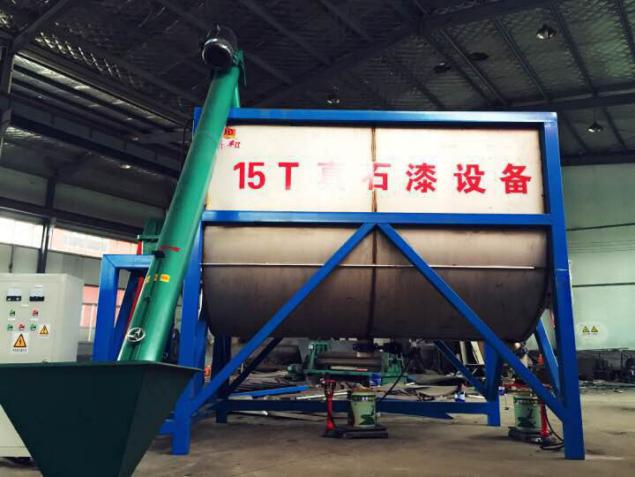

First, the horizontal real stone paint has compact structure, small floor space, convenient feeding and feeding, and high production efficiency. It can be lifted up and down and used flexibly. Motors, reducers, flip motors, infrared sensors, left and right safety latches, stainless steel gates, and power distribution cabinets are all ready for installation. All products must be commissioned before leaving the factory. After connecting to the home for three-phase power, it will be able to start production, saving time and trouble.

Second, with mobile loading machine: when loading, the feeding machine is pushed over to feed, after the material is finished, the loading machine is removed, which does not affect the unloading, which is quick and convenient.

Third, the discharge port is equipped with stainless steel valve and quick shut-off valve. When stirring, the stainless steel valve is closed and the seal is tight. It is easy and quick to open the quick cut valve when loading!

Five, horizontal true stone paint mixer features: 1 will turn up and down, easier to clean. 2 The design capacity is larger, 30% larger than the similar equipment capacity. The 3rd-layer spiral belt and the mixing drum have a scraping knife in the middle. The mixing is more thorough, no dead angle, no residue, and the product quality is higher. 4 equal quality, lower peer prices

4. The most wearable spiral belt is the thickest and widest in the same industry and durable. 2. Add the cooked tape on the scraping knife to avoid hard contact with the wall tube and damage the wall tube. 3. Install a safety guardrail above the mixing drum to prevent personal injury caused by employee mistakes.

5. Central control switch, push-button operation. Concise and simple, easy to operate!

2. Specifications

|

Model

|

DB-5

|

DB-10

|

DB-15

|

DB-20

|

DB-30

|

DB-40

|

|

Power (KW)

|

22

|

30

|

45

|

55

|

75

|

90

|

|

Stirring amount(T)

|

5

|

10

|

15

|

20

|

30

|

40

|

|

Dimensions (M)

|

4.3*3*3

|

5*3*3.5

|

5.5*3.5*3.5

|

5.5*4*4

|

6*4.5*4

|

6.5*5*4

|

|

Equipment weight (KG)

|

3000

|

3700

|

4100

|

4500

|

5800

|

6800

|

No article.